Toffee Making Machine

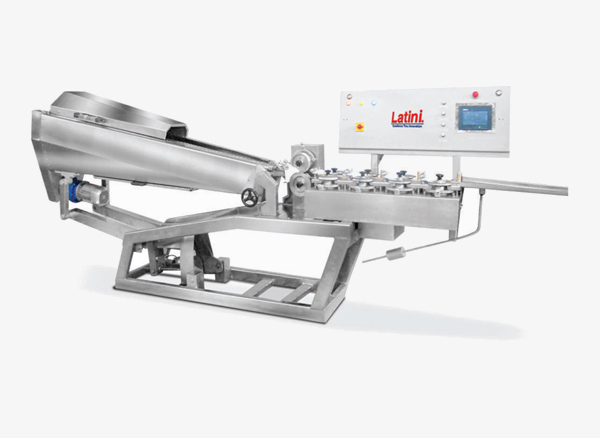

BATCH FORMING AND SIZING MACHINE BRS - 90 V

Related Machinery

Get A Quote

BATCH FORMING AND SIZING MACHINE BRS - 90 V

Latini's electro-mechanical batch roller offers reliability and precise control over the forming of your candy/toffee/lollipop rope. The latest technology gear drive systems provide a smooth and quiet operation, while the heavy-duty construction makes this a very sturdy, durable machine. The stainless steel cones also have heavy-duty internal reinforcement as well as special permanently lubricated bearings. Includes a watertight electrical control panel and adjustable legs that allow for easy alignment to any forming machine.

Latini’s Universal Batch Sizing Machine delivers a predetermined candy rope with the help of conical rollers. The conical-shaped rollers work with an alternate movement ensuring the mass of the candy, toffee, lollipop or other related products remains malleable enough to be processed further in the candy-making process. Latini’s Batch Sizing Machines or Batch Former has the feature of a motorized up-down and electronically forward reverse system that keeps the control in the operator’s will for better utilization and production. The rollers of our Candy Batch Sizing Machines can be removed without the need for any additional tools. Keeping in mind the good manufacturing practices for confectionery manufacturers, the Batch Sizing Machines ha been developed to assist a thorough and through-out cleaning of the machine, including the rollers. These stainless steel batch rollers are spring-loaded for automatic adjustment, saving you the hassle of frequent manual adjustments. The variable rate of speed is available to ensure uniformity of the finished product. In addition to that, Latini also offers left or right-hand-operated units as per your requirements.

One could easily say that a Batch Forming Machine is almost a necessity for every confectionery manufacturing facility. Without a dependable Batch Forming Machine, the forming and sizing process of your candy deters greatly which in turn also affects the shape and even the speed of candy forming. To ensure that you don’t end up with greater quantities of de-shaped or ill-weighted candies, it is imperative that a confectionery manufacturing facility invests in a complete Batch Forming Machine.

Latini offers you a variety of Confectionery Manufacturing Machines, complete from batching and dissolving of sugar and processing of syrup, to the cooking, cooling, pulling, rope sizing, forming, wrapping, and packing all from one source. What else would a person searching for Batch Forming Machines require more when they have found a one-stop solution by Latini-Hohberger Dhimantec?

Latini’s BRS-90 aids in the preparation of candy, toffee, and lollipop mass by forming and sizing it to the desired size and width. The confectionery mass is fed to the Uniplast Sweet Forming Machine and Batch Forming Machine available with the Rope Sizing Machine. The confectionery sector has benefited from Latini’s creative and tried-and-true solutions. Our 75-year experience sets us different and allows you to perfect your product. Whether you're a large organization or a newcomer to the sector, we'll help you choose the correct equipment, develop recipes, and train you on how to get the most out of your new candy machinery.

- Stainless Steel Rollers

- Batch Roller and Rope sizer integrated on a single sanitary stainless steel platform.

- The radiant heating system in the batch roller keeps the mass warm and

- One-cluster pulling head for better grip and pull (*Optional- as per requirement)

- Installed with Rope Feed control system, to adjust the rope speed automatically

- One point grease lubrication system for easy & accurate maintenance

- Uses a Screw-type direct drive mechanism instead of a hydraulic system using fewer moving parts and is easy to maintain.

Three and Five Stage Rope Sizer

- Universal Rope sizer for making and feeding rope for hard candy, Toffee, Lollipops, etc.,

- Stainless steel sizing wheels with one vertical pulling head for better rope grip and pulling

- Variable speed can be synchronized with forming and cutting machines

- Optional Heating mechanism of sizing wheels for Flat Lollipop's production

- Auto-rope controller with the synchronization system

BRS - 90 Series Batch former with rope sizer combination is available with single to six sets of sizing wheels and optional 4 wheel cluster after the batch former.

| Specifications | |

|---|---|

| Capacity | 240 lbs (110 kg) per batch |

| Power Load | 6 kw |

| Net Weight | 2000 lbs (900 kg) |

| Gross Weight | 2500 lbs (1150 kg) |

| Other options / Autres options / Otras opciones : | |

| BRS - 90 Series Batch former with rope sizer combination is available with single to six set of sizing wheels and optional 4 wheel clusterafter the batch former. / La combinaison formeur de lot série BRS - 90 et encolleur de corde sont disponibles avec un à six ensembles deroues de calibrage et 4 motifs de roues en option après le formeur de lot. / La máquina formadora de lotes en combinación con calibradoraSerie BRS - 90 está disponible con un conjunto de una a seis ruedas dimensionadoras y un panel opcional de 4 ruedas tras la máquinaformadora de lotes. | |

FORMATION DE LOT ET ENCOLLEUSE BRS - 90 V

Le formeur de lot et l'encolleur Latini sont disponibles en différents types de combinaisons. L'entreprise installe leformeur de lot , le motif, l'encolleuse et le tapis à corde pour assurer un alignement correct. La plate-forme unique etle tableau de commandes électriques ajoutent beaucoup de propreté et de commodité.

MÁQUINA FORMADORA DE LOTESDIMENSIONADORA BRSY- 90 V

La máquina dimensionadora y formadora de lotes Latini está disponible en varios tipos de combinaciones. Máquinaequipada de formación de lotes para empresas, panel, máquina dimensionadora y una alfombrilla de cuerdagarantizan la alineación adecuada. La plataforma única y el panel de control eléctrico aportan limpieza ycomodidad.